CREATION OF SEARCH SYSTEMS OF THE WHEEL TYPE

JSC "Firma TVEMA" steadily and tirelessly improves diagnostic systems for various elements of the railway infrastructure. Of course, the system of non-destructive testing of rails cannot remain on the sidelines. The company is constantly making efforts to continue the path to new achievements in the field of flaw detection.

Once upon a time, the next stages of "non-destructive inspiration" were, first, the transition from a centering friction-sliding system to a system operating on the principles of friction-rolling. Then there was a widespread transition to the introduction of a contactless magnetic centering system, the principle of operation of which is based on the interaction of the magnet of the centering system and the rail.

The same can be attributed to the hardware – the dynamic range of recorded data of ultrasonic channels is steadily increasing – first there was a flaw detector "ECHO-COMPLEX", then "ECHO-COMPLEX-2", after "ECHO-COMPLEX-3", in the future "ECHO-COMPLEX-4" …

Types of search systems are becoming more and more perfect – the number of acoustic units is increasing, their geometry is changing, the stability of acoustic contact is increasing, including in the most negative conditions, the probability of failure is decreasing.

More and more functions are being introduced into the INTEGRAL software, and the era of automated flaw analysis is inevitably coming.

The laboratory of NDT JSC "Firm TVEMA" is on the crest of a wave that carries everything new to the railways of the countries of the world.

Nevertheless, it is time to give the ultrasound public access to some secret materials – since 2017, the company has been developing in the field of search systems that work from the point of view of providing acoustic contact with the object of control – the rail, based on new principles of selecting material interacting with the ultrasound input surface.

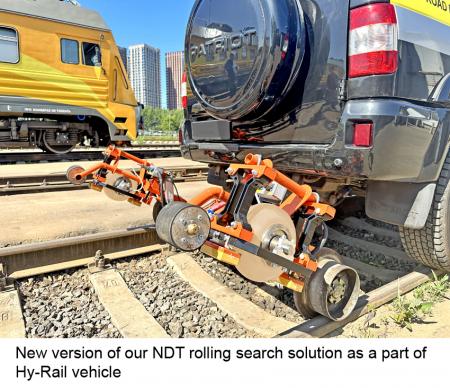

In this part, significant progress has been made in the creation of search systems of the so-called rolling search unit type. Thus, the elastic material helps to increase the stability of the acoustic contact in conditions when the profile of the ultrasound input surface changes in plan (for example, if there is a vertical step in the bolted joint area). However, the presence of an elastic wheel material creates significant difficulties in terms of the directivity of the acoustic field of the transducer in the case when the ultrasound input surface changes in the profile, which leads to the need for periodic adjustment of the angle of inclination of the wheel system (for example, when entering a curved section of the track and exiting it, as well as in the presence of lateral wear).

It should also be borne in mind that the sliding search systems have their advantages, i.e. it helps to increase the stability of the acoustic contact in the case when the surface of the ultrasound input changes in the profile. This does not create difficulties in terms of the directivity of the acoustic field of the transducer. Therefore, there is no need to periodically adjust the angle of inclination of the sliding system in curves and in the presence of lateral wear.

Combining types of search systems is the future of flaw detection.