Rail profile inspection systems

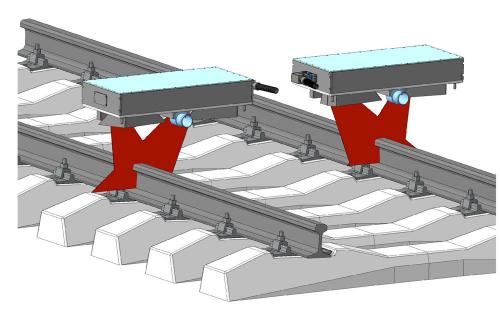

Rail profile monitoring systems are an advanced version of the system for monitoring and assessment of track geometry parameters, which make it possible to perform monitoring of the complete rail profile at high speeds.

Purpose

The full rail profile monitoring system is designed for high-speed shooting of the full rail profile along the movement trajectory of diagnostic tools in the speed range from 0 to 250 km/h. The system is installed on the frame of the car bogie.

Additional three-dimensional cameras that monitor the outside rail surface make it possible to estimate their wear and all the necessary additional parameters from an external inactive side.

Additional lasers provide a single line of exposure with the main lasers, which makes it possible to increase the power and intensity of their illumination to the rails surface and successfully combat against possible exposure in sunny weather, obtaining high-quality data at any season of the year, under any weather conditions, and also makes possible to maintain reliable operation with "shiny" (wet, grinded, polished) rails.

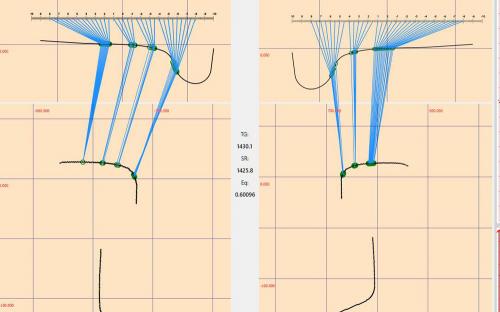

To determine the stability of the rolling stock, reduce the forces arising from the interaction of the wheel with the rail, reduce the wear of rail head and the surface of wheel thread, the lateral wear of the rails during high-speed movement, it is necessary to take into account the interaction between the wheel and the rail, namely the effect of an equivalent conicity on the movement of the rolling stock. When the wheel of the standard conical profile interacts with the rail, the wheel pair shifts in a transverse direction relative to the track axis in accordance with the conicity parameters. Monitoring of the equivalent conicity using the full rail profile monitoring system makes it possible to maintain the proper level of movement safety at the high-speed sections of the railways.

Specialized optical circuit of the system makes it possible to recognize the railway crossings and their elements. The camera's field of view makes it possible to perform an automated analysis of the track components, such as rail joints, sleepers and bonds. Availability of monitoring from the outside makes it possible to perform reliable identification of defective bonds on the outer surface.

Software

All received information is processed in real time, recorded and documented for further analysis and planning of works on the routine maintenance and repair of the track. The software of the system makes it possible to compare information on the actual condition of the rails with data from the database of the track section, to perform automatic comparison and generate reports and recommendations for managing and operating units of the railways.

Advantages

- Low cost.

- Compact, light and simple design, which makes it extremely easy to install and dismantle the entire system.

Scope of application

The network of railways of the Russian Federation and foreign countries.